Search the Community

Showing results for tags 'bend'.

-

Started doing a bunch of sheet metal bending and trying to streamline our process. We have 50+ dies all labeled and organized on a rack, but at my computer we don't have reference to these dies other than the bend radius. My thought is that if we measure them all and make models we would be able to...

-

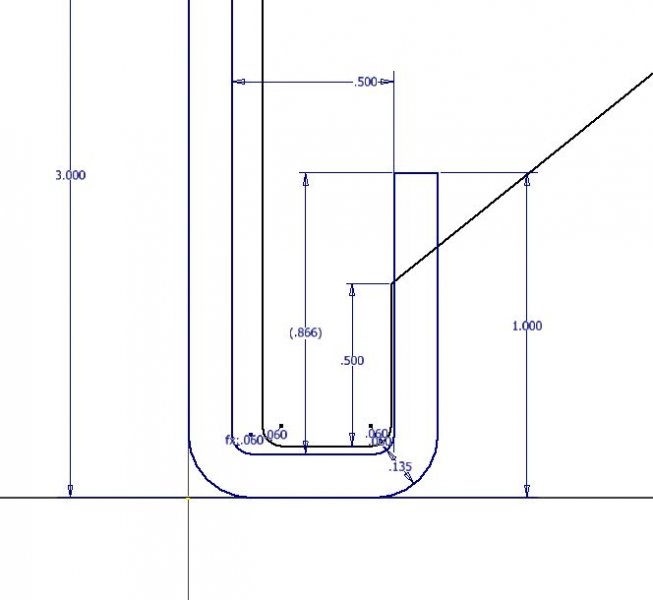

We had a custom part needed to be fabricated, guy bent bar stock to desired shape, gave to me. Now I am trying to reverse engineer to get manufacturing drawings and try to figure out the best way to get a straight length. I created a 3d sketch and sweep on the line for the shape. I can measure the s...